-

AcerinoxHIGHLIGHTSConsolidated Management Report

Discover all about Acerinox in our Consolidated Management Report

-

SolutionsHIGHLIGHTS+ than 18,000combinations, the widest range of products and solutions

-

Shareholders & InvestorsHIGHLIGHTS

-

SustainabilityHIGHLIGHTS

References in circular economy:

Volume of recycled material in the production process

>90%

Recycled content rate of our products

>70%

Reuse of waste generated

- People

-

Press room

Stainless Steel Grades

Austenitic

They are iron, chromium, nickel and carbon alloys. Adding nickel modifies the structure of these materials.

The stainless steel that characterises this group is AISI 304, EN 1.4301.

This is the stainless steel group with significant benefits for manufacturing components and equipment, as well as service performance. They have excellent forming properties, great corrosion resistance and are very easy to weld.

Ferritic

Ferritic stainless steels are also iron, chromium and carbon alloys, with higher chromium and lower carbon content than martensitic stainless steels. The typical values of these elements are C < 0.10%, Cr 16 – 18%.

Duplex

Duplex stainless steels are microstructurally constituted by two phases: ferrite and austenite. As alloying elements, they contain iron, chromium, carbon and nickel, with the latter being at a lower percentage than in austenitic stainless steels.

In general, they have higher mechanical properties and corrosion resistance than ferritic and austenitic stainless steels.

Martensitic

These stainless steels are iron, chromium and carbon alloys, with typical compositions of C:0.10% and Cr:12-14%.

The stainless steel that characterises this group is AISI 420, EN 1.4028.

Martensitic stainless steels suffer structural changes at high temperatures; therefore, they usually undergo hardening and tempering heat treatments.

After these treatments, these materials obtain high mechanical properties and sufficient corrosion resistance. Their most typical application is cutlery.

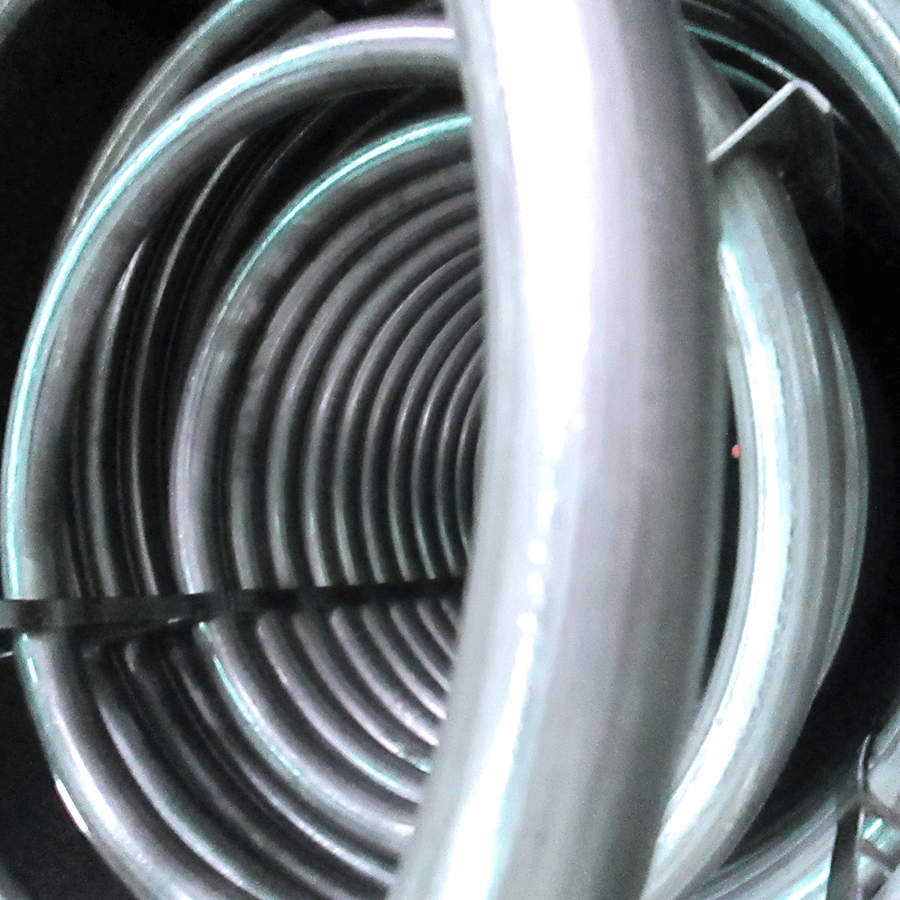

Welding

The widest range of wire stainless steels for welding materials.