-

AcerinoxHIGHLIGHTSConsolidated Management Report

Discover all about Acerinox in our Consolidated Management Report

-

SolutionsHIGHLIGHTS+ than 18,000combinations, the widest range of products and solutions

-

Shareholders & InvestorsHIGHLIGHTS

-

SustainabilityHIGHLIGHTS

References in circular economy:

Volume of recycled material in the production process

>90%

Recycled content rate of our products

>70%

Reuse of waste generated

- People

-

Press room

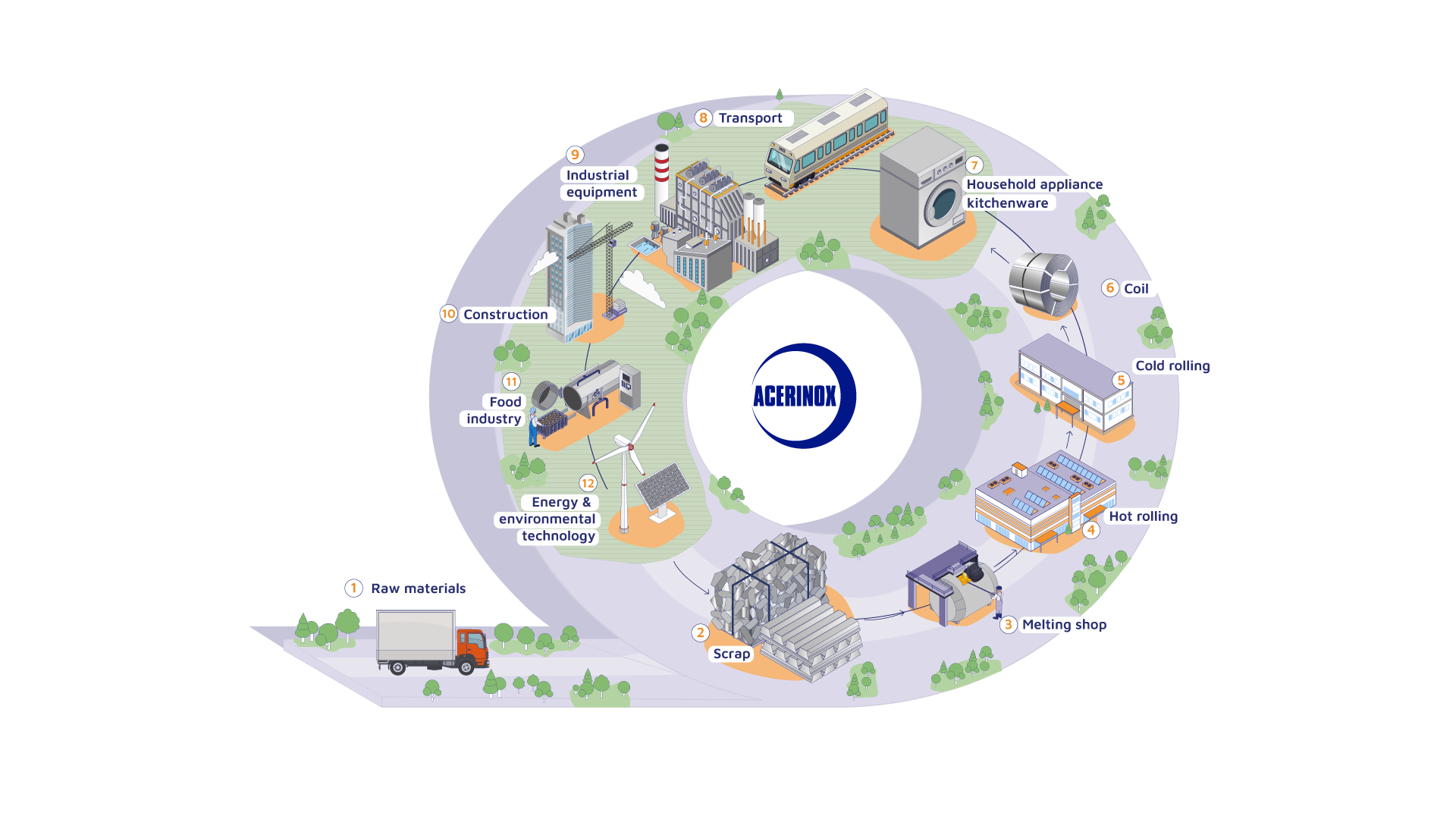

Circular Economy

Stainless steel is a sustainable material by definition

To ensure sustainable growth it is essential to make efficient use of resources and promote initiatives that help to evolve towards a circular economy model.

Circular economy in Acerinox

Reduce by 90% the waste sent to landfill taking as a reference the 2020 data.

E-Waste

In Malaysia, E-waste is categorised as Scheduled Wastes under Code SW110, First Schedule, Environmental Quality (Scheduled Wastes) Regulations 2005. To ensure the implementation of sustainable e-waste management, the consumer is responsible for disposing of their e-waste via the retailer, registered collectors or licensed recovery facilities.

The first phase of the project involved dedicating an area at Bahru’s plant for the collection of household e-waste from employees’ homes/daily lives. The second phase will look to expand, through Bahru’s CSR programme, the collection of household e-waste from the sponsored school and the nearby community and neighbourhood.

Kentucky Excellence in Environmental Leadership

NAS is also a great recycler of scrap metal, and advocates reducing waste generation, reusing materials and separating metallic and non-metallic materials. NAS is one of the first members of the Kentucky Excellence in Environmental Leadership (KY EXCEL) programme and has reached the Master membership level.

Recovery of neutralisation sludge

The Bahru factory continued its project to recover acid pickling neutralisation sludge for processing into building bricks, which has the approval of the Malaysian Department of Environment (DOE). This project was in collaboration with the University Technology Malaysia Construction Research Centre (UTM CRC) and Eco Greenbuild Industries. The end product is made from 100% recycled material, of which 70% is acid pickling sludge from stainless steel, clay sludge from the ceramic industry and coal bottom ash from power plants. The remaining 30% is comprised of recycled cement. The product meets the national requirements of the Construction Industry Development Board (CIDB) Building Standards and is certified in accordance with SIRIM MS 2282-3: 2010. The advantages of these bricks compared to conventional bricks include greater uniformity, increased compressive strength, lower moisture penetrability, fire resistance, improved sound insulation and greater dimensional accuracy.