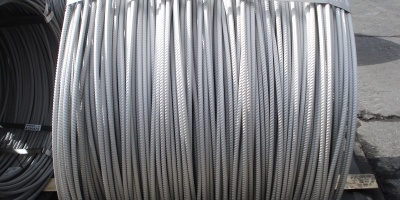

Reinforcement wire

High corrosion resistance, high ductility and high fire resistance.

Stainless steel grades / packaging

|

|

EN |

Packaging |

|

Reinforced bar |

1.4462-1.4482 |

Trancane |

|

Prestressed bar |

1.4462-1.4482 |

Trancane |

Dimensions

STRAIGHTNESS: 0.004*L (L= bar length)

|

Nominal Ø |

Max diference |

|---|---|

| 5 | 0.50 |

| 6 - 8 | 1.00 |

| 10 | 1.50 |

LENGTH +25 mm

Specifications may vary depending on grade and finish. Other specifications or sizes on request.

Stainless steel grades / packaging

|

|

EN |

Packaging |

| Cold drawn short round bar |

on request | palet |

Dimensions

STRAIGHTNESS/OVAL-SHAPED: according to EN 10218-2. Class 1

|

Length |

Straightness tolerance |

|---|---|

| <500 | 0.50 |

| >500 ≤1000 | 2.00 |

Lengths >1000 mm, rolling test on inclined plane will be applied

MAXIMUM DEPTH ON DEFFECT/ROUGHNESS

Crack detector: NO

As it is a cold drawn material, surface deffects may persist

|

Finish |

Ø ≤10 |

Ø >10 |

Roughness |

|---|---|---|---|

| All | ≤0.07 | ≤0.08 | ≤1.50 |

TOLERANCES

LENGTH according to EN 10218-2. Class 1

|

Length |

Length |

|---|---|

|

≤300 |

+0.50 mm |

|

>300 y ≤1000 |

+1.00 mm |

|

>1000 y <2000 |

+0.10% |

DIAMETER

Tolerance according to ISO 286-2

|

Nominal diameter |

h8 |

h9 | h10 | h11 |

|---|---|---|---|---|

| >5 to ≤6 | 0.018 | 0.030 | 0.048 | 0.075 |

| >6 to ≤10 | 0.022 | 0.036 | 0.058 | 0.090 |

| >10 to ≤14 | 0.027 | 0.043 | 0.070 | 0.110 |

Desviation values are "in minus" over the nominal size. I.e. 5 mm diameter, has a tolerance h9 type, which means +0, -0.030 mm or 4.970/5.00 mm.

Materials may also be manufactured according to EN 10218-2 using diameters intervals T1, T2, T3, T4 and T5 from the minimum permissible value of +0.025 mm in diameter ≥5.00 mm.

For ferritic stainless steel grades only ISO H9 tolerance can be guaranteed.

Data subject to changes according to international standards and working practices.

Other grades on request: customer.service@acerinox.com